Stick Noodle Machine / Stick Noodle Production Line Line

Traditional Italian/Chinese Spaghetti Making

(hot air dehydration simulating sundrying)

▶️ Sick Noodle / Spaghetti Line 1 ▶️ Sick Noodle / Spaghetti Line 2

We always use the best machines designed and made by us and our selected partners for our turnkey projects

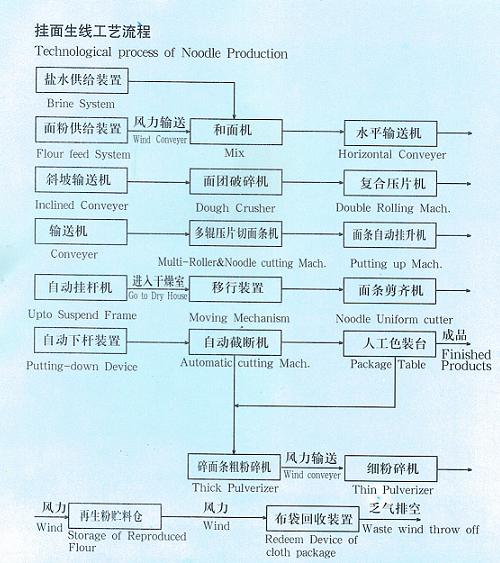

This is an automatic heated-air-dried spaghetti pasta production line. The uncooked freshly shredded spaghetti is dried slowly in a large drying chamber that simulates the sundry process in the old dates. This pasta production line is used to make traditional Italian sundry spaghetti, usually using durum wheat semolina. In China wheat flour is used, an alkaline solution is usually added to give the spaghetti springy, chewy texture, and the final product is known as guamian or stick noodles.

We provide stick noodle machines and production lines with product output capacities ranging from 2 to 8 tons per 8 hours. We show case here as an example the line of output capacity of 5 tons per 8 hours.

The process of our stick stick noodle machines has been mature, steady and easy to control. The product quality is wonderful; the life span of the machines is outstanding.

The Da Sanjiang stick noodle machines are highly automatic. The temperature of drying room and humidity are automatically controlled with very little human intervention is less, craft work is logical, the quality and shelf life of the noodle products are much better than others in China. We achieve the highest power saving and environment protect standards. Our company got the best technicians and processing equipment. The assembly accuracy of our stick noodle machines is high, accident rate is low. We take the lead.

General Description of the stick noodle machines

1. production capacity: 5t/8h

2. No. of worker: about 10 persons

3. workshop area: 150x60 feet(single floor)

4. Total Power: 100kw, 380V/50Hz

Introduction to the stick noodle production line

1. Full automatic wind power feeder of the complete set of the stick noodle machines

The worker put in the flour, wind power blow them into mixer, this device not only save labor, but also keep the sanitation, it also can be made that conveyer from flour storage room to machine room.

2. Super powerful mixer for the stick noodle machines

There are 2 mixers running alternately in this line, while one is feeding the flour timely, another will mix flour. It will let the dough go to next program continuously. The mixer has a rubbing device, which is two slowly agitating claw of SS material.

The dough come out from the mixer will be low temperature, ripe, keep good quality flour. in prevent from the double shaft high speed hot mixer destroying the gluten and the molecular structure. After mixing, the door will open, the dough will fall onto the dough wakening machine. Specification Rubbing time: around 12m( Max. 350kg/pot).

3. Rolling machines of the stick noodle processing equipment

It consist of nine pairs of the roller, which is made of nickel molybdenum alloy steel (the same hard with the flour roller) and the driver is easy, logical, and low error rate. It equip with a stepless frequency converter, it runs steady, noiseless, save power. Use hand wheel to adjust the clearance.

4.Automatic hanging-up machine of the stick noodle machine assembly

The length of the noodle can be adjusted, no break on pole, no falling pole, no accident.

5. Drying room of the stick noodles line

Drying is the most important section in this production line, which adopts rope way type with low temperature, humidity keeping and hot wind. In 3 drying rooms, the temperature is different, highest would be around 35 °C and there are fans to keep the steam outlet.This way can keep the noodle deep dry and save power consumption. In the whole drying room, the temperatures of three areas can be adjusted through the wind door and valve. In this line, we have our special technique to keep the certain humidity to prevent from noodle too dry or only dry at the surface, (especially for the thick noodle), this is also an important way to raise the capacity, extend the validity of noodle, the most impressive feature of the noodle made by this stick noodle production line is: sweet smelling, chewy, smooth, leveling shade, no breaking at the bend, no sourness, long validity. The hang noodle is being conveyed, the speed can be controlled by the frequency converter, automatically fall into the cutting machine.

6.Automatic cutting machine

One of the biggest advantage of this stick noodle machine is, you don’t need so much operators to control frequently, when the noodle start from coming out from drying room, to being cut to output product, you need only one technicians to control, and the program is automatic control. The cutter is using the no teeth blade, the noodle length is the same, broken percentage is low, whole strip percentage is over 90%, all kinds of length can be cut through changing the component. This line showing not consist of the chip collecting and convey device.

7.Automatic noodle chips collect system (optional unti for the stick noodle line)

The chips caused by the cutting machine, will be grinded by smash machine, and blew to the tiny smashing machine, finally go into the regeneration storehouse, and rational get into the feeder, blew to the mixer with the new flour. In China, we are the only company having this technique to retrieve the chips. This type of chip collect system is sanitary, all of the chips are running in pipe. Dislike the soaking craftworks, this way would not smelly, Keeping the noodle quality and lower the cost.

8.HWJ-400 horizontal type auto packaging machine for the stick noodle machines line

It consists of automatic weighing machine, automatic feeding machine and automatic packing machine, becoming the full automatic packaging machine in the true sense. It is suitable for the vermicelli factory to pack products with compound bag. It has merits of reasonable structure, high automaticity and simplicity operating. The daily output may reach 3 to 5 tons (may be different depending on the weight of the package). It has received the consistent high praise in the long-term use of user community. In raw material selection, mainly use steel structure and stainless steel material in the contact part with food.